Stereolithography (SLA) 3D printing services utilize advanced technology that creates three-dimensional objects by curing liquid photopolymer resin with UV light, layer by layer.

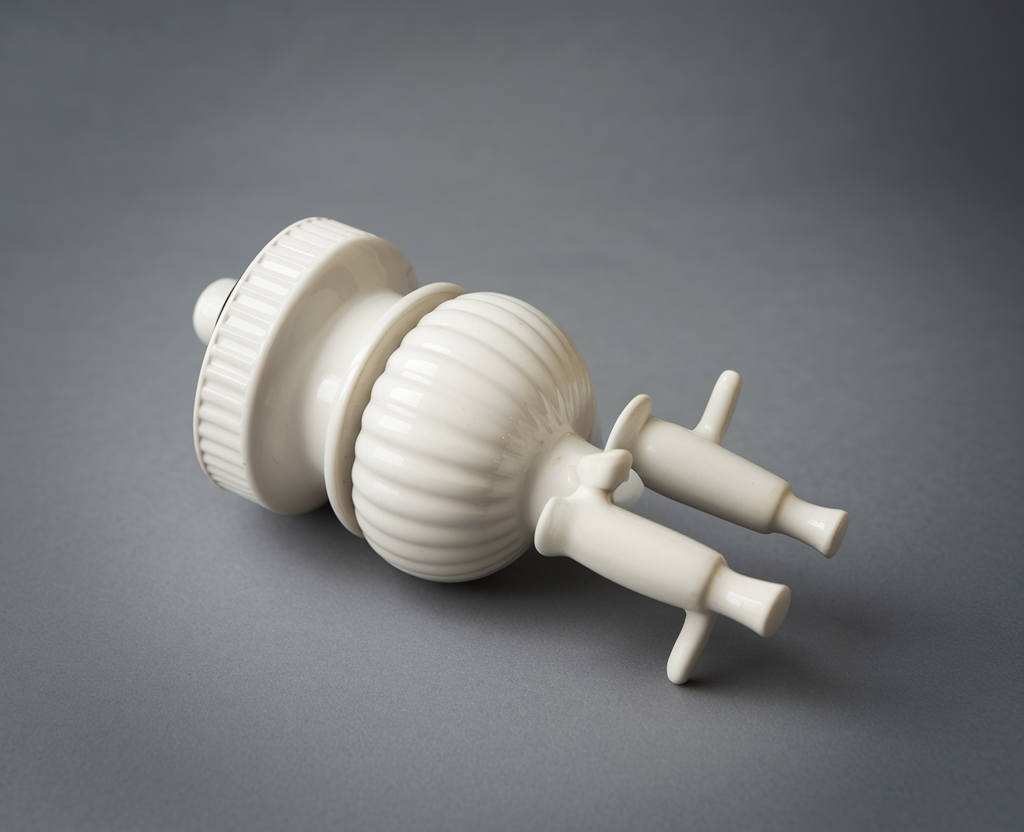

This precise manufacturing method achieves exceptional dimensional accuracy of ±0.2% and can produce features as small as 0.2mm, making it ideal for both prototyping and production runs. SLA offers impressive surface finishes comparable to injection-molded parts, with layer thicknesses between 50-200 microns. The process supports various engineering resins, including durable options like Accura Xtreme White 200 and heat-resistant Accura Bluestone.

Understanding the full capabilities of SLA technology reveals its significant advantages for modern manufacturing needs.

orders of 1000 or more available

Stereolithography (SLA) represents a sophisticated 3D printing technology that harnesses liquid photopolymer resin and ultraviolet light to create highly detailed three-dimensional objects. This advanced manufacturing process, which falls under the category of vat photopolymerization, builds parts layer by layer with exceptional precision and dimensional accuracy of ±0.2%.

The SLA process enables the production of intricate components with feature sizes as small as 0.2 mm, making it particularly suitable for applications requiring fine detail and complex geometries. Using high-quality materials such as Formlabs and 3D Systems Accura resins, SLA technology delivers consistent results across prototyping and production applications. The versatility of these materials allows manufacturers to meet diverse industry requirements while maintaining high standards of quality.

To achieve ideal results, SLA-printed parts undergo essential post-processing steps, including the careful removal of support structures and thorough UV curing. These final stages are vital for ensuring the structural integrity and longevity of the printed components. The combination of precise printing capabilities and extensive post-processing makes SLA an ideal choice for both prototype development and small to medium-scale production runs.

Modern engineering resins form the backbone of SLA 3D printing technology, offering manufacturers diverse material options to meet specific application requirements. These materials range from Strong and Transparent to Flexible and High Temperature variants, each engineered for distinct purposes in prototype development and manufacturing.

Nylon PA12 stands out as a versatile material in selective laser sintering, packing impressive mechanical properties into a lightweight frame

Did you fail to locate what you were searching for? Please feel free to contact us for more information.

Standard lead times for SLA 3D printing usually range from one to five business days. The exact timeframe depends on the complexity, size, and specific requirements of the part being produced.

SLA offers a wide selection of engineering resins, such as Accura ClearVue, known for its optical clarity, and Accura Xtreme White 200, valued for its durability and strength. These materials are suitable for a variety of applications, including aerospace components, automotive parts, and aesthetic prototypes.

SLA technology is renowned for its high-resolution output and exceptional surface quality. The ultra-smooth finishes rival those of injection-molded parts, making it an excellent choice for aesthetic models and prototypes where detail and visual appeal are crucial.

Post-processing options include support removal, UV curing for enhanced strength, and finishing techniques such as polishing and painting. These steps can be customized to achieve the desired appearance and functionality.

Quality assurance involves rigorous pre-printing checks, real-time monitoring during production, and thorough inspections after printing. These measures ensure structural integrity and consistent surface finish quality for all parts.

Yes, SLA is capable of producing large and intricate geometries with a build volume of up to 1500 x 750 x 550 mm. Its precision and efficiency make it suitable for both small-scale prototypes and sizable, complex designs.