Nylon PA12 Grey is a high-performance thermoplastic powder used in Selective Laser Sintering (SLS) 3D printing. The material excels in creating complex geometries while maintaining structural integrity. Understanding its full capabilities reveals why it's becoming an industry standard.

A versatile powerhouse in 3D printing materials, Nylon PA12 Grey is a high-performance polyamide powder that combines durability, flexibility, and chemical resistance. We've found this material particularly notable for its impressive mechanical properties, featuring a density between 0.90 and 0.95 g/cm³ and a tensile strength of 45 ± 3 N/mm². These specifications make it an excellent choice for demanding applications where strength and reliability are essential.

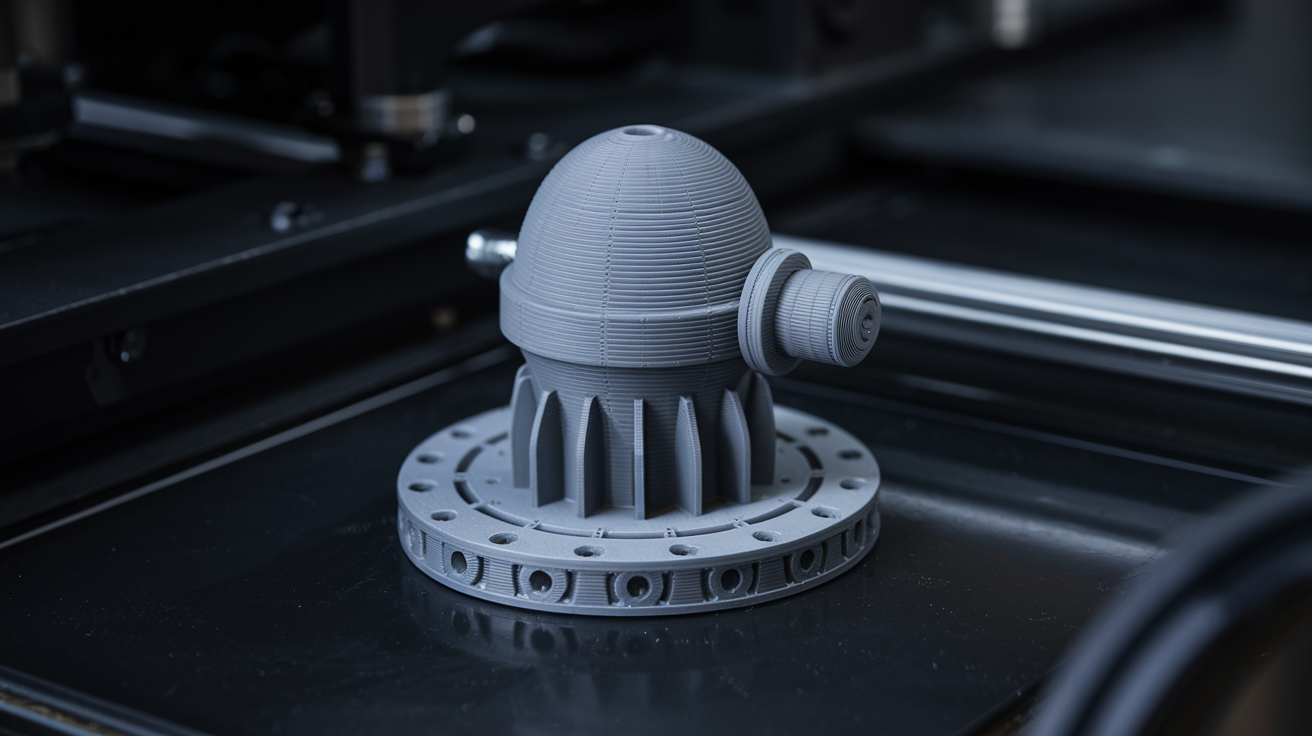

When we work with Nylon PA12 Grey, we use Selective Laser Sintering (SLS) technology, specifically through EOS P395 or EOS P396 machines. This advanced manufacturing process allows us to create complex geometries and interlocking components with exceptional precision. The material's natural finish presents a distinctive grey, granular appearance, though we can enhance its surface quality through polishing techniques.

To guarantee peak performance in your designs, we recommend following specific dimensional guidelines. For flexible components, we maintain a minimum wall thickness of 0.8 mm, while rigid structures require at least 2 mm thickness. These parameters help ensure the structural integrity and functionality of your printed parts.

Successful printing with Nylon PA12 Grey demands careful attention to specific design guidelines. We'll need to maintain minimum wall thicknesses of 0.8 mm for flexible components and 2 mm for rigid structures to guarantee proper durability in our printed parts. When designing assemblies, it's essential to keep a spacing of at least 0.5 mm between parts and walls, which allows for effective drainage of excess material during the printing process.

We must carefully consider our geometry choices, particularly in areas subject to heavy loads. Since thin walls can warp under stress, we recommend thickening critical structural areas to maintain integrity. To optimize material usage and reduce costs, we can implement hollowing techniques in our designs, but we'll need to include two drainage holes for excess powder removal. It's significant to recognize that Nylon PA12 printing only supports single object files, so we'll need to focus our design optimization efforts accordingly. By following these requirements, we can create successful prints that maintain both structural integrity and cost-effectiveness while meeting the material's specific printing constraints.

Building on our established design guidelines, Nylon PA12 Grey has proven its worth across numerous industries and applications. We've seen remarkable success in mechanical prototyping, where its 45 ± 3 N/mm² tensile strength and inherent flexibility make it perfect for creating complex geared systems and articulated components. The material's exceptional chemical resistance has opened doors to various industrial applications, ensuring longevity in demanding environments.

We're particularly impressed with how Nylon PA12 performs in creating intricate educational tools and ornamental pieces, where detailed features and interlocking parts are essential. Its versatility shines through in applications that demand both functional excellence and aesthetic appeal, allowing designers to push creative boundaries while maintaining structural integrity. In the automotive and aerospace sectors, we've witnessed outstanding results in producing lightweight yet durable components, where precise weight distribution and structural strength are critical factors. The material's ability to support complex geometries while delivering consistent performance has made it a go-to choice for manufacturers who need reliable, high-quality parts that can withstand real-world challenges.

When it comes to finishing Nylon PA12 Grey prints, you'll find two primary surface options at your disposal: raw sandblasted and polished. The raw sandblasted finish offers an economical choice, presenting a grey, granular surface with some porosity that's perfect for functional prototypes or parts where aesthetic appeal isn't the primary concern.

For projects requiring a more refined appearance, we offer mechanical polishing as an enhanced finishing option. This process transforms the natural texture into a smoother surface, greatly improving the visual appeal of your printed objects. Regardless of which finish you select, we'll maintain our standard layer thickness of 100 µm and an impressive accuracy of ± 0.45% across your prints.

| Mechanical Properties | Conditions | Unit | Value |

|---|---|---|---|

| Density of laser-sintered part | EOS-Method | g/cm3 | min. 0.90 / max. 0.95 |

| Tensile Modulus | DIN EN ISO 527 | N/mm2 | 1700 ± 150 |

| Tensile strength | DIN EN ISO 527 | N/mm2 | 45 ± 3 |

| Elongation at break | DIN EN ISO 527 | % | 20 ± 5 |

| Melting point | DIN 53736 | °C | min. 172 / max. 180 |

Don't miss out on exciting opportunities to expand your horizons and achieve greatness. Take the first step today!