We offer professional Selective Laser Sintering (SLS) 3D printing services, using high-powered lasers to transform powdered thermoplastics into precise, functional parts layer by layer. Our technology accommodates projects from single prototypes to 10,000-piece production runs, with a build volume of 700mm x 380mm x 580mm and layer thickness of 100 microns. We work primarily with durable nylon materials (PA12 and PA11) and offer extensive post-processing options including sanding, dyeing, and painting.

Our quality control guarantees dimensional accuracy of +/- 0.3mm per 25.4mm, making us ideal for aerospace, automotive, medical, and consumer goods applications. Explore our capabilities to discover how SLS can revolutionize your manufacturing needs.

orders of 1000 or more available

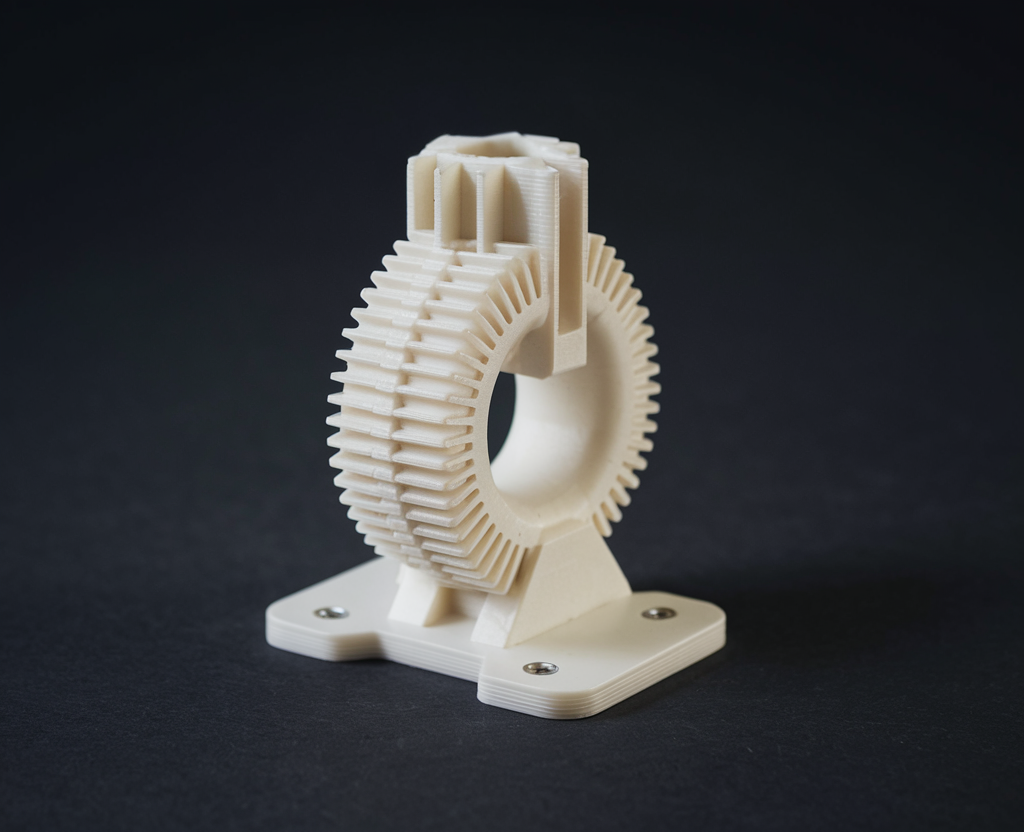

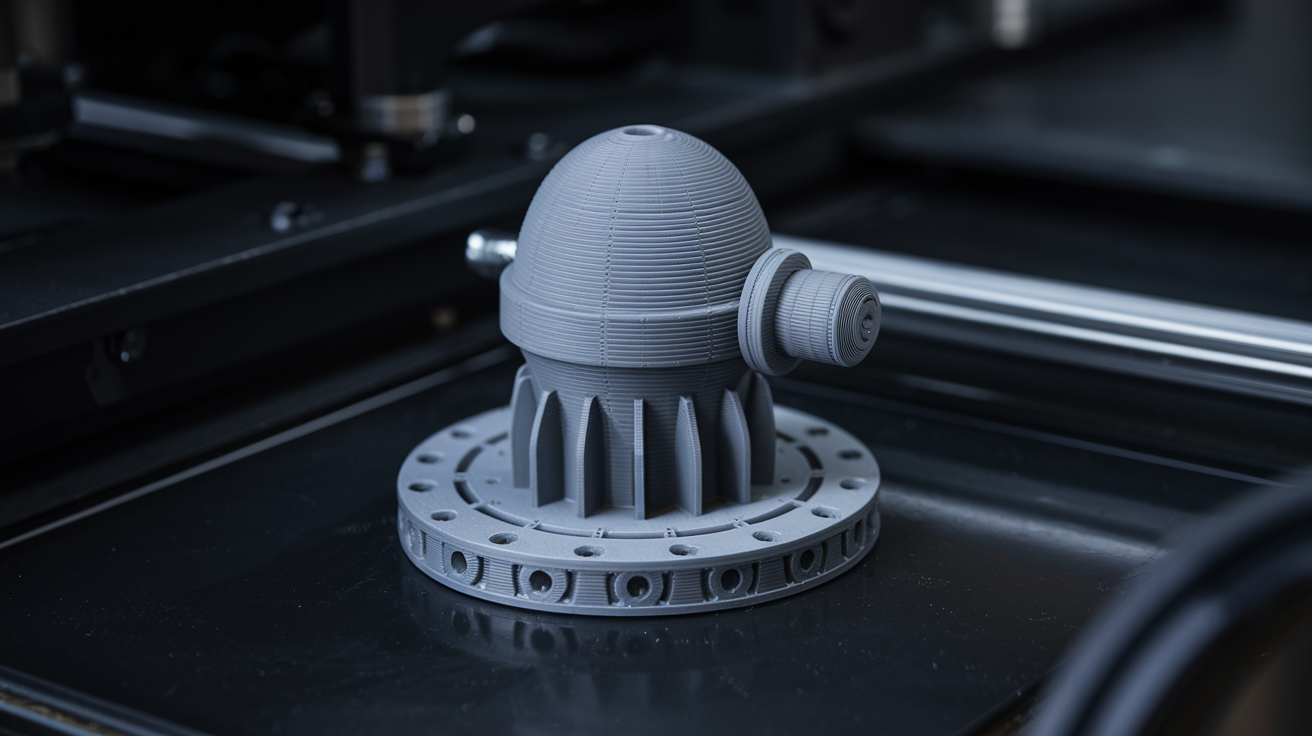

SLS technology represents a groundbreaking advancement in 3D printing, utilizing a high-powered laser to transform powdered thermoplastic materials into solid parts. We're able to create complex geometries through this process, which builds objects layer by layer using primarily nylon-based materials. What makes SLS particularly efficient is its preheating mechanism, which warms the powder just below its melting point before sintering.

One of the most impressive aspects of SLS is that we don't need support structures during the build process, making it highly versatile for complex designs. The technology offers substantial build volumes of up to 700mm x 380mm x 580mm, allowing us to produce relatively large parts in a single print. We achieve remarkable precision with standard layer thicknesses of 100 microns and a laser diameter of 0.4mm, ensuring detailed results.

What sets SLS apart is its isotropic nature - parts maintain consistent mechanical properties regardless of build orientation. We can consistently achieve dimensional accuracy within +/- 0.3mm per 25.4mm of part dimension, with minimum tolerances of 0.25%, making it an ideal choice for functional prototypes and end-use parts.

Diverse materials available for SLS printing, starting with the versatile Black Nylon PA12 are perfect for complex parts requiring durability. Our material selection guide also covers finishing options, from natural white's raw texture to enhanced black dye and performance paint finishes that boost both aesthetics and durability.

Nylon PA12 stands out as a versatile material in selective laser sintering, packing impressive mechanical properties into a lightweight frame

This remarkable material combines environmental responsibility with exceptional performance characteristics, making it an ideal choice for advanced manufacturing applications

A versatile powerhouse in 3D printing materials, Nylon PA12 Grey is a high-performance polyamide powder that combines durability, flexibility, and chemical resistance

An advanced 3D printing material that combines sustainability with exceptional performance. This carbon fiber-reinforced polyamide, derived from renewable castor oil, offers impressive strength-to-weight ratios and durability.

A bio-derived 3D printing material that's revolutionizing industrial manufacturing. Combines exceptional mechanical properties with essential electrostatic discharge protection.

This material combines exceptional rubber-like elasticity with superior shock absorption and durability, making it ideal for automotive parts, sports equipment, and medical devices.

A specialized flame-retardant polyamide 12 material designed for SLS 3D printing that we've found offers exceptional fire resistance without toxic halogen emissions.

A high-performance 3D printing material that combines polyamide 12 with glass fiber reinforcement, creating exceptionally durable parts through selective laser sintering (SLS)

Did you fail to locate what you were searching for? Please feel free to contact us for more information.

SLS offers several advantages:

By leveraging SLS technology, Proforge3D delivers reliable, high-quality results for a variety of industries and applications.

SLS printers have fixed build volumes that determine the maximum size of a single print. At Proforge3D, the largest build volume we offer is 700mm x 380mm x 580mm. However, larger parts printed in SLS may have a higher likelihood of warping or deforming. For optimal precision, we recommend splitting larger models into smaller sections that can be printed separately and assembled afterward.

Lead times for SLS prints depend on the size, complexity, and material used for the project, as well as the current production workload. For most small to medium-sized parts, orders are completed within 2-5 business days. Larger or more intricate designs, especially those requiring post-processing, may take longer to fulfill.

The cost of SLS printing is primarily determined by the amount of material used and the size of the part. Smaller, dense parts typically cost less, while larger parts that occupy significant space in the build chamber are priced higher. Additional services, such as post-processing (sanding, dyeing, sealing, or painting), contribute to the overall cost, as these processes require extra time and materials.

At Proforge3D, quality control is a multi-step process:

Our commitment to rigorous quality control ensures every product we deliver meets or exceeds expectations in precision and performance.

Yes, Proforge3D provides a wide range of post-processing options to enhance your parts, including sanding, dyeing, painting, and surface finishing. We work closely with you to determine the most suitable finishing techniques to meet your project’s requirements.