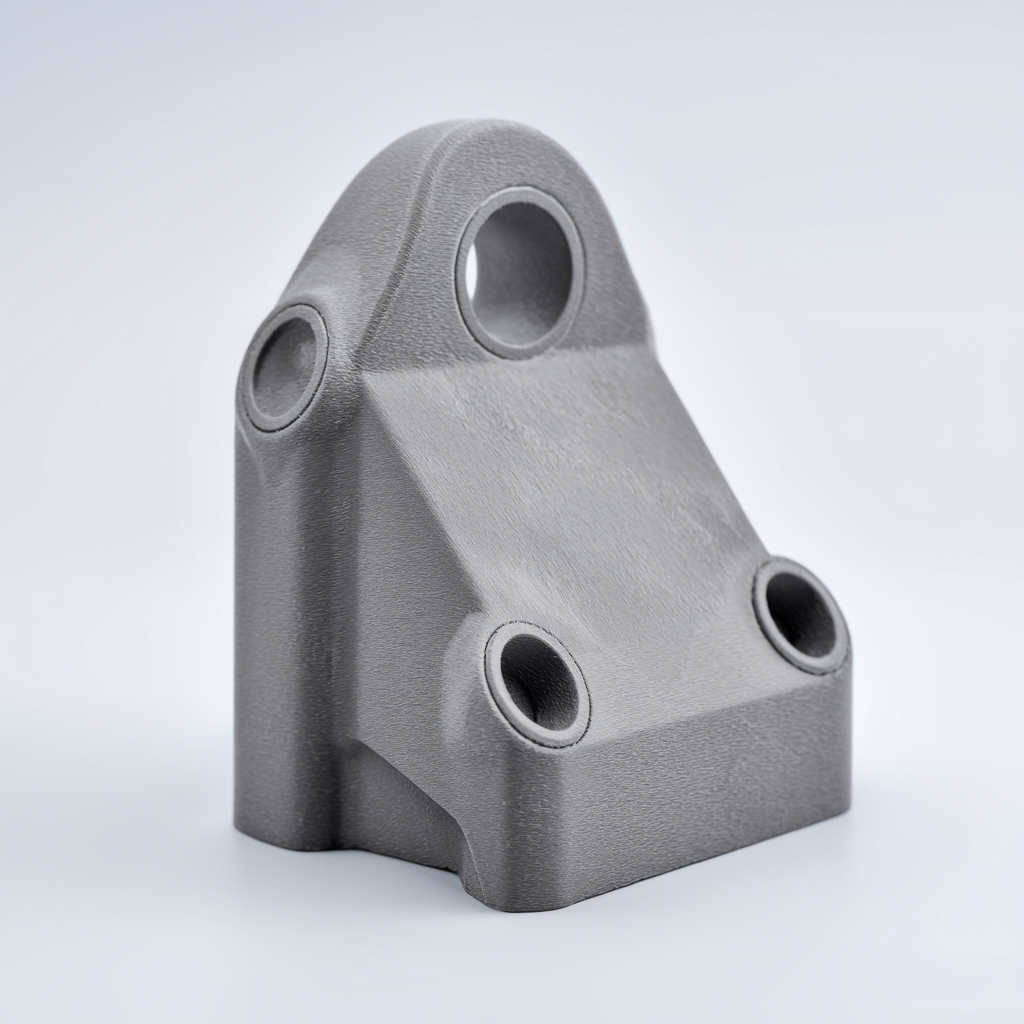

Multi Jet Fusion PA 12 is a versatile thermoplastic material designed for advanced industrial 3D printing applications. With an exceptional strength-to-weight ratio and superior chemical resistance, it delivers impressive tensile strength of 50 MPa and 20% elongation at break.

Made from premium-grade polyamide powder, Multi Jet Fusion PA 12 is a sophisticated thermoplastic material engineered specifically for 3D printing applications. This versatile material demonstrates exceptional mechanical characteristics, combining superior elasticity with remarkable impact resistance of 3.7 kJ/m² and a tensile modulus of 1700 MPa, making it ideal for demanding industrial applications.

With a density of 1.01 g/cm³, Multi Jet Fusion PA 12 delivers consistent performance across various manufacturing scenarios. The material's chemical resistance properties, particularly against hydrocarbons and aldehydes, enhance its suitability for industrial components and functional prototypes. Its compliance with RoHS/REACH standards and biocompatibility certification further expand its application potential into medical fields.

Distinguished by its exceptional mechanical properties, Multi Jet Fusion PA 12 stands out as a premier thermoplastic material in the 3D printing industry. Its impressive tensile strength of 50 MPa combined with a 20% elongation at break guarantees reliable performance in demanding applications, while maintaining a superior strength-to-weight ratio due to its 1.01 g/cm³ density.

Notably, Multi Jet Fusion PA 12's compliance with RoHS/REACH regulations and biocompatibility certifications extends its applications into medical and consumer products. These certifications, combined with its superior mechanical properties and chemical resistance, position Multi Jet Fusion PA 12 as an ideal choice for professionals requiring high-performance 3D printing materials.

Multi Jet Fusion PA 12 has established itself as a versatile 3D printing material across numerous industrial sectors. Its exceptional impact resistance and elasticity make it particularly valuable in automotive manufacturing, where it excels in producing durable interior components that meet stringent industry standards.

The material's applications extend considerably into the medical field, where its superior chemical resistance and biocompatibility enable the production of reliable healthcare devices and components. In aerospace and consumer goods manufacturing, PA 12's capability to create intricate, high-precision parts such as gears and hinges demonstrates its technical versatility and reliability.

Educational institutions frequently employ PA 12 for functional prototyping, while various industries utilize it for both prototype development and final production runs. The material's low moisture absorption characteristics make it especially suitable for outdoor applications and industrial environments where stability is essential. This property guarantees that components maintain their dimensional accuracy and structural integrity over time, even in challenging conditions. These diverse applications showcase PA 12's position as a fundamental material in modern manufacturing processes across multiple sectors.

The impressive performance of PA 12 across industries stems from its carefully engineered technical specifications. With a density of 1.01 g/cm³ and a tensile modulus of 1700 MPa, this material delivers an ideal balance between structural integrity and flexibility, making it suitable for demanding applications. The impressive impact strength of 3.7 kJ/m² further enhances its durability and reliability in various use cases.

A key technical advantage of Multi Jet Fusion PA 12 lies in its superior chemical resistance, particularly against hydrocarbons and aldehydes, which contributes to its longevity in industrial environments. The material demonstrates notable thermal properties, with a transformation point at 187°C (369°F), enabling post-processing modifications to meet specific design requirements. This characteristic provides engineers and designers with additional flexibility in product development and refinement.

| Mechanical Properties | Conditions | Unit | Value |

|---|---|---|---|

| Density of part | ASTM D792 | g/cm3 | 1.01 |

| Tensile Modulus (XY) | ASTM D638 | MPa | 1700 |

| Tensile strength (XY) | ASTM D638 | MPa | 50 |

| Elongation at break | ASTM D638 | % | 17 |

| Impact strength (XY) | ASTM D256 | kJ/m2 | 3.7 |

Don't miss out on exciting opportunities to expand your horizons and achieve greatness. Take the first step today!