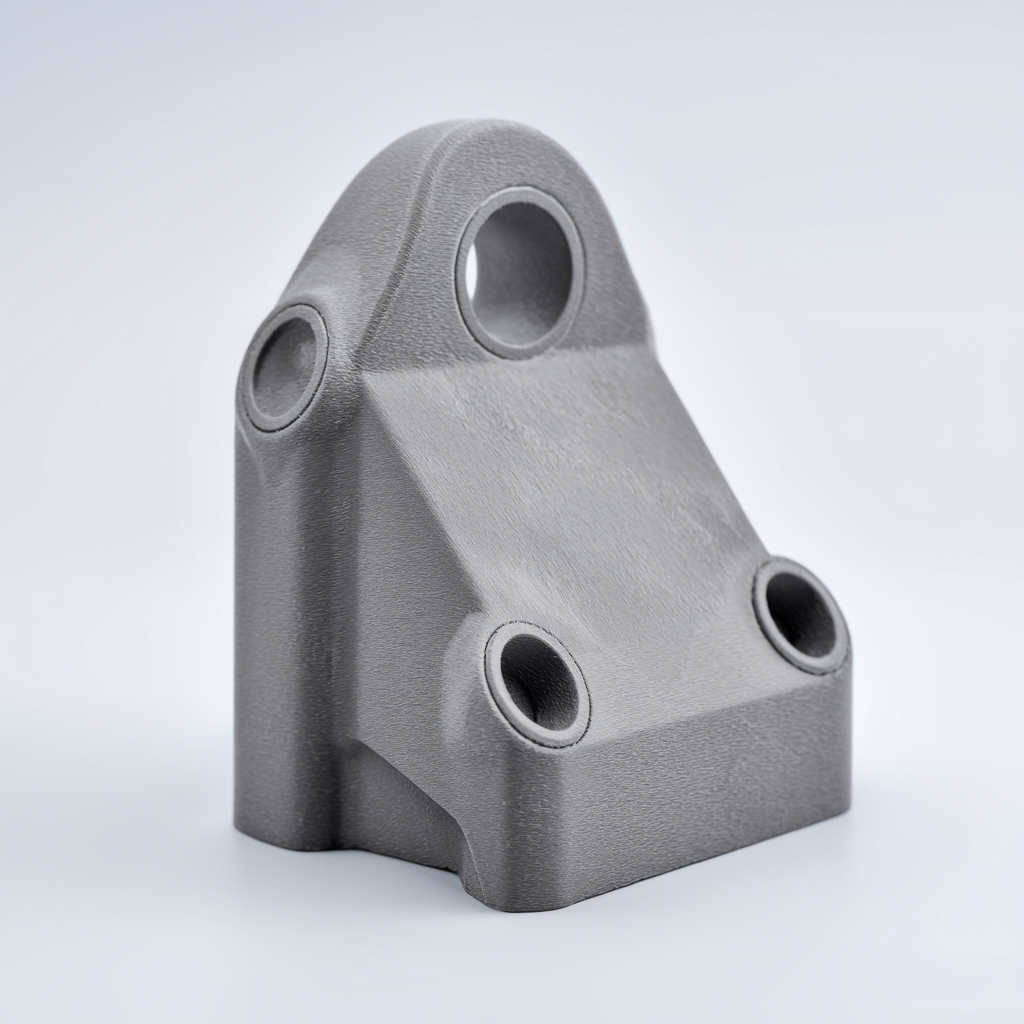

HP Multi-Jet Fusion (MJF) is an advanced 3D printing technology that produces high-quality thermoplastic parts with exceptional precision and speed.

The process builds components layer by layer at 80μm thickness, achieving ±0.3% dimensional accuracy across a generous build volume of 380 × 284 × 380 mm. MJF utilizes PA12, TPU01, and PP materials, offering tensile strengths up to 48 MPa and flexural strength of 70 MPa, making it ideal for both prototypes and end-use parts.

With standard lead times of three business days and various surface finishing options including dyed, tumble, and vapor smoothing, MJF delivers professional-grade results for diverse manufacturing needs. Exploring this technology reveals its full potential for modern production requirements.

orders of 1000 or more available

HP Multi-Jet Fusion (MJF) represents a sophisticated 3D printing technology that constructs detailed thermoplastic parts through a layer-by-layer process using multiple printing agents. This advanced manufacturing method delivers exceptional dimensional accuracy of ± 0.3% with precise layer heights of 80μm, enabling the creation of complex geometries and intricate features within its generous build volume of 380 × 284 × 380 mm.

The technology stands out for its impressive mechanical properties, producing parts with high tensile strength up to 48 MPa, making it particularly suitable for both functional prototypes and end-use production components. MJF supports various materials, including PA12 Grey and PA12 Black, which provide excellent structural integrity and consistent performance across applications.

One of the key advantages of MJF technology lies in its efficient production capabilities, offering quick turnaround times with standard lead times beginning at just three business days. The process excels in creating precise, functional parts that meet demanding industrial requirements while maintaining fine feature resolution throughout the build. This combination of speed, accuracy, and material versatility positions MJF as a leading solution for professional-grade additive manufacturing needs.

Material selection forms the foundation of successful Multi-Jet Fusion 3D printing, with a range of high-performance options designed to meet diverse manufacturing requirements. The primary materials available include Jet Fusion PA12, TPU01, and PP, each offering distinct characteristics tailored to specific applications and performance needs.

Knowing Multi Jet Fusion PA 12's exceptional properties unlocks endless possibilities for creating robust, functional parts across various industries

Offering unmatched sustainability and strength, PA 11 HP revolutionizes 3D printing with its bio-based composition and remarkable impact resistance.

Get ready to revolutionize your manufacturing with Jet Fusion PP, the game-changing polypropylene material that's redefining 3D printing possibilities.

A revolutionary flexible 3D printing powder that combines exceptional strength and resilience, transforming manufacturing possibilities across automotive, medical, and industrial applications.

Did you fail to locate what you were searching for? Please feel free to contact us for more information.

The build volume for MJF technology is 380 × 284 × 380 mm. This size accommodates both large parts and multiple smaller components in a single production run, making it versatile for various applications.

MJF offers exceptional precision with a layer thickness of 80µm and dimensional accuracy of ±0.3% (minimum ±0.3 mm). This ensures high-quality results for even the most intricate and complex geometries.

Common materials include PA 12 Grey and PA 12 Black, which provide excellent tensile strength of 48 MPa. These materials are durable and suitable for functional prototypes as well as end-use parts.

MJF parts can be finished in various ways, including natural finish, dyed black, tumble smoothing, or vapor smoothing. These options allow customization to meet both aesthetic and functional needs.

MJF offers fast production times, with standard lead times starting from just 3 business days. This rapid turnaround is ideal for businesses needing quick prototyping or production.

Yes, MJF excels in creating complex geometries without the need for support structures. This capability, combined with its precision and material strength, makes it perfect for demanding applications in various industries.