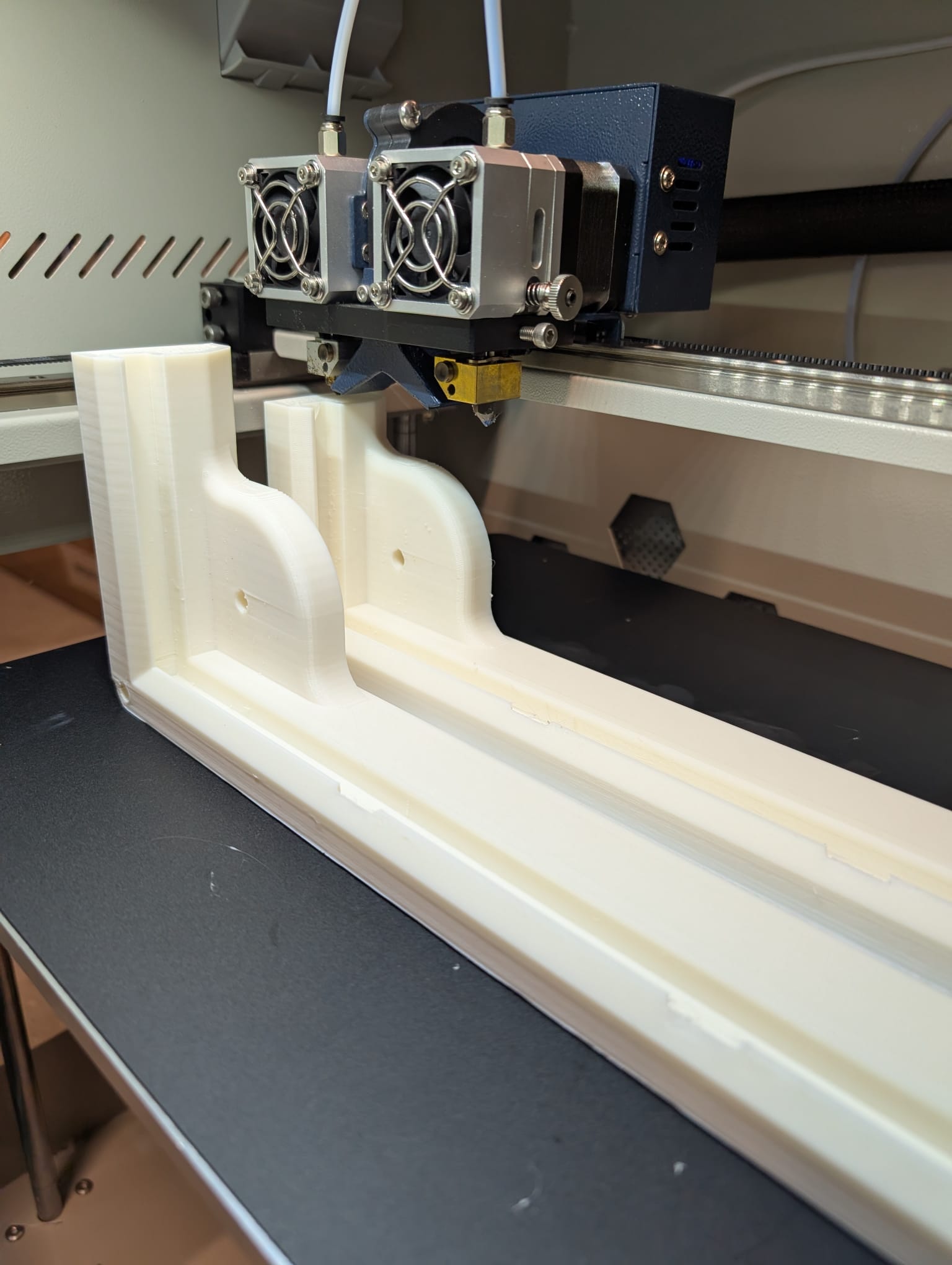

We've seen 3D printing transform industrial design through its ability to create rapid prototypes and on-demand production capabilities. This technology allows designers to quickly produce complex models using real-world plastics at a fraction of traditional manufacturing costs.

We've seen weight reductions of up to 50% compared to traditional methods, particularly beneficial in automotive and industry applications. The ability to quickly implement design changes based on customer feedback creates unprecedented manufacturing agility. There's much more to discover about this revolutionary technology's impact on modern industrial design.

In automotive manufacturing, 3D printing revolutionizes production with faster speeds and lighter parts, but there's more to this game-changing technology.

Our team will setup a secure location for you to upload your file. Work with our team to get the right file for the next stage.

Our team will provide a thourough quote after discussing the right materials, quantities and the turn around time that will meet your needs. When ready, the order is placed and paid for.

Manfacturing begins for your purchase and design. Our team will examine and inspect the parts for quality and approve it for delivery.

We will ship to your location. Shipping will be available across Canada or if you're local to our location you can pick it up in person.

Let's explore how 3D printing has transformed industrial design through rapid manufacturing capabilities and enhanced prototyping workflows.

Here are some of the ways we are helping:

Industrial design's rapid prototyping capabilities have been transformed by 3D printing technology. We're now able to create complex models using real-world plastics without the considerable tooling investments that traditional manufacturing methods like injection molding require. This advancement has revolutionized our approach to product development and testing.

We've seen particularly impressive results in automotive prototyping, where next-day production capabilities allow us to rapidly iterate designs and collect immediate feedback. The flexibility of 3D printing lets us produce customized, low-volume items on demand, which greatly reduces the overhead costs we'd typically encounter with large-scale manufacturing operations.

Nearly every advantage of 3D printing converges in on-demand production, where we're able to create custom products without the considerable startup costs of traditional manufacturing. We've found that this approach notably reduces overhead expenses, making it particularly valuable for specialized products and niche market demands. The elimination of extensive tooling investments means we can offer cost-effective solutions for even small production runs.

This efficiency extends to the production of complex prototypes that we use for thorough testing and validation. By maintaining quick feedback loops, we're constantly improving our industrial design projects and delivering better results. The flexibility of on-demand production means we can adapt quickly to changes, making it an invaluable tool in modern industrial design.

Many businesses are discovering considerable cost advantages with 3D printing over traditional manufacturing methods. We're seeing substantial reductions in overhead costs compared to conventional processes like injection molding and CNC machining, particularly for smaller production runs where traditional tooling costs would be prohibitive.

We're also noticing how localized manufacturing in Canada is creating additional cost benefits. By reducing shipping distances and simplifying logistics, businesses can considerably lower their transportation expenses. This accessibility to cost-effective manufacturing has opened doors for startups and small businesses, allowing them to enter the market without the substantial financial commitments typically associated with traditional manufacturing methods.

While cost savings drive many companies toward 3D printing, the technology's ability to reduce component weight has become another compelling advantage. We're seeing remarkable results with weight reductions of up to 50% compared to traditional manufacturing methods, which is transforming how we approach industrial component design.

What's particularly valuable is how 3D printing eliminates the need for additional support structures in many designs, further reducing overall component weight. Through rapid prototyping, we can quickly test and modify designs to optimize weight reduction strategies. This iterative process allows us to fine-tune components until we achieve the ideal balance between strength and weight, resulting in more efficient and lighter industrial products that meet modern engineering demands.

Frequently Asked Questions About How 3D Printing Is Changing The Automotive Industry

3D printing is widely used in industries such as automotive, aerospace, consumer goods, and industrial equipment. Its ability to produce lightweight, cost-effective, and complex prototypes makes it ideal for these fields.

3D printing eliminates the need for expensive tooling and setup fees, enabling cost-effective production for prototypes and small production runs.

Yes, 3D printing can reduce component weight by up to 50% using advanced geometric structures like lattices, while maintaining strength and durability.

We use real-world plastics, engineering-grade thermoplastics, and composites to create durable and lightweight products that meet industry standards.

Our next-day turnaround capabilities allow for rapid prototyping, enabling faster design iterations and immediate feedback.

On-demand production involves creating custom products without extensive setup costs or tooling. This approach is ideal for niche markets and small production runs, offering rapid delivery and flexibility.

Absolutely. 3D printing excels in low-volume production by minimizing overhead and delivering high-quality, customized items efficiently.

We create intricate prototypes that test both performance and aesthetics, ensuring precise design validation before moving to production.

Yes, localized manufacturing, reduced material waste, and shorter supply chains contribute to a smaller environmental footprint with 3D printing.

Our online quoting system provides instant cost estimates and timelines, streamlining the planning and production process.

Leave the questions here, we will answer you soon.