3D printing has transformed automotive manufacturing, letting us produce complex parts faster and more efficiently than ever before. We're seeing unprecedented speed in production, with some components manufactured in as little as one day while maintaining rigorous quality standards

This revolutionary approach reduces costs through streamlined production methods and lower inventory requirements, while ensuring strict quality control. The impact of these innovations extends far beyond just faster manufacturing.

In automotive manufacturing, 3D printing revolutionizes production with faster speeds and lighter parts, but there's more to this game-changing technology.

Our team will setup a secure location for you to upload your file. Work with our team to get the right file for the next stage.

Our team will provide a thourough quote after discussing the right materials, quantities and the turn around time that will meet your needs. When ready, the order is placed and paid for.

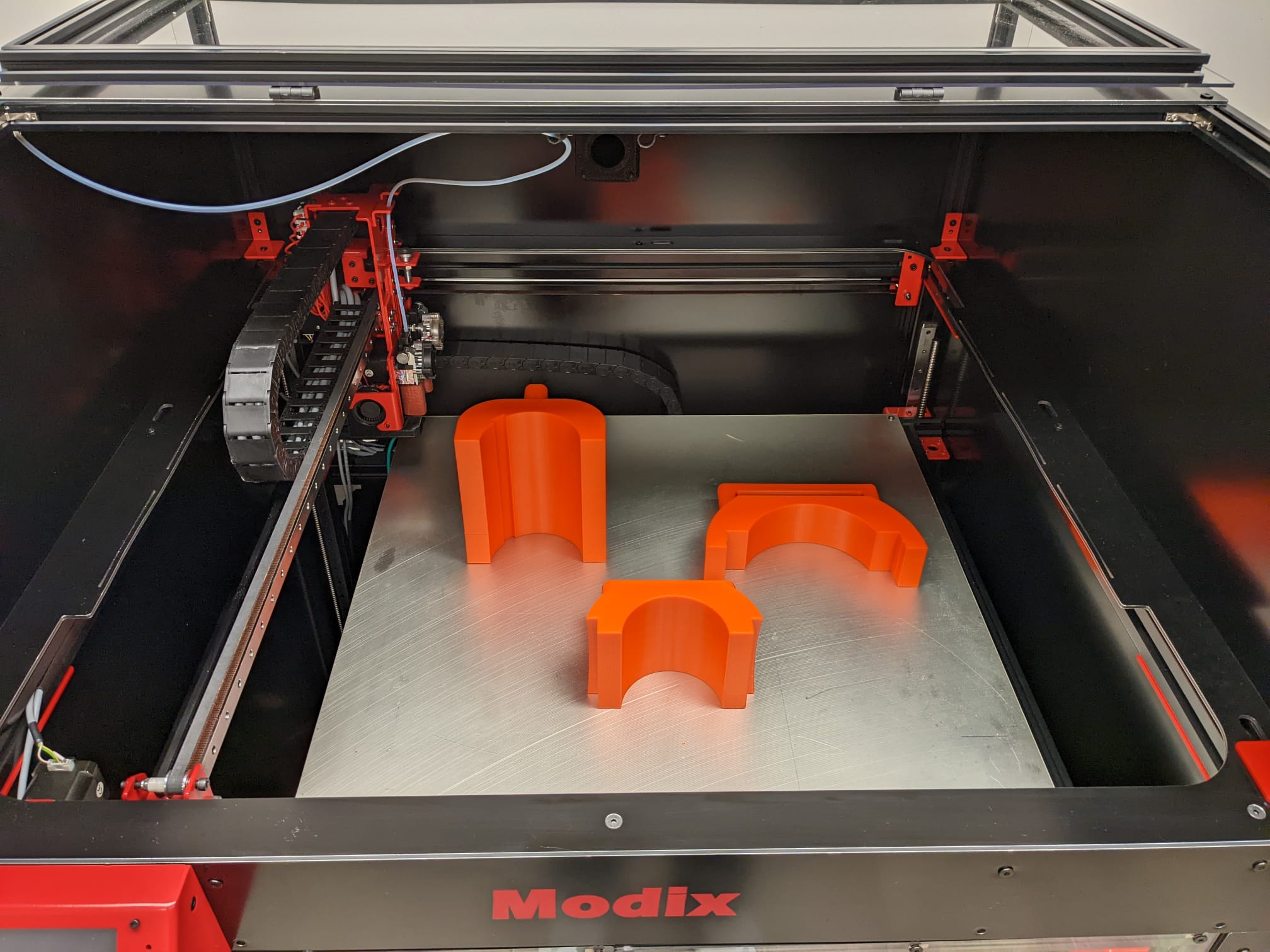

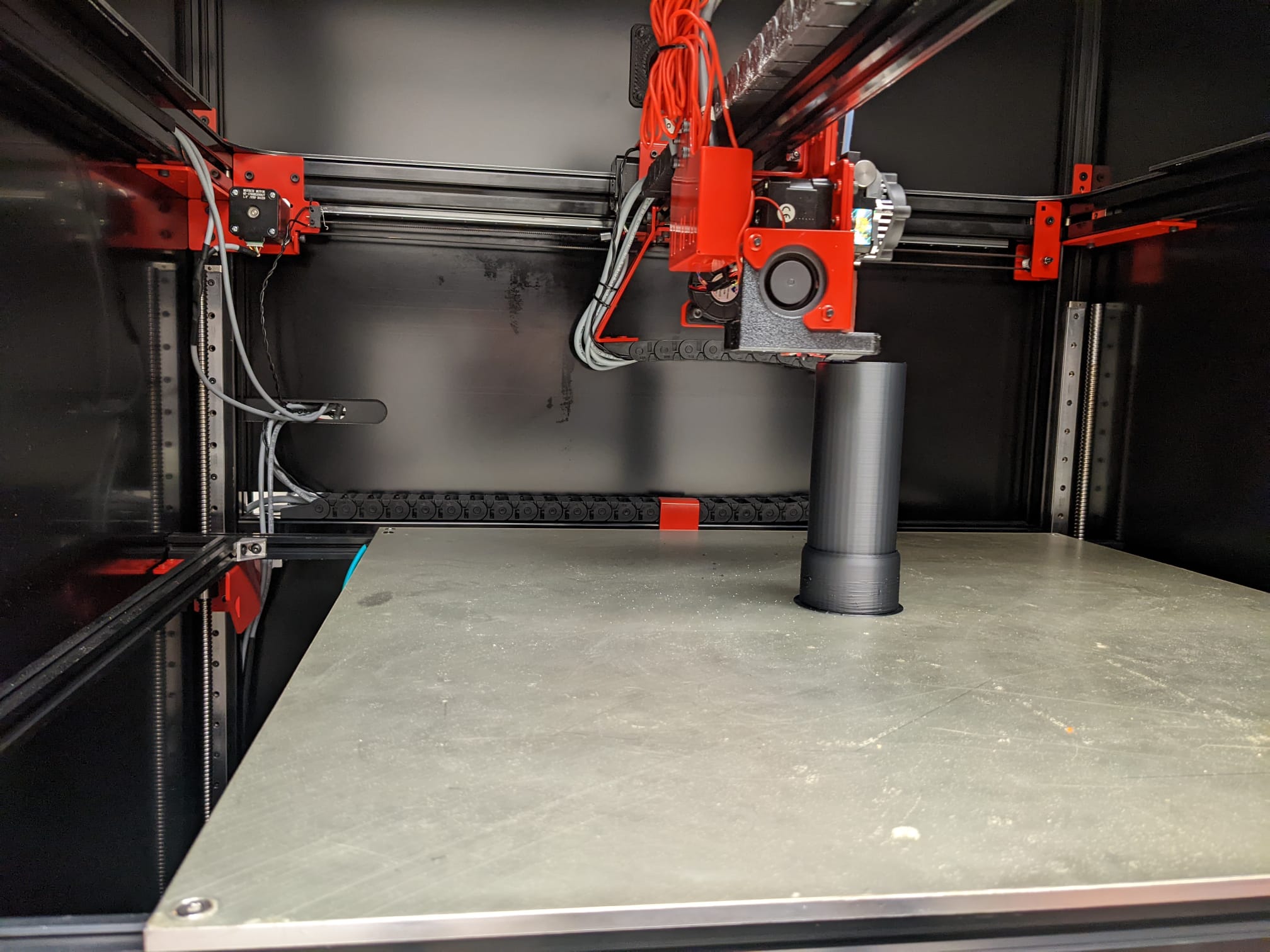

Manfacturing begins for your purchase and design. Our team will examine and inspect the parts for quality and approve it for delivery.

We will ship to your location. Shipping will be available across Canada or if you're local to our location you can pick it up in person.

The technology enables precise prototypes with tolerances of +/- 0.1mm and creates remarkably lighter components using advanced materials like carbon fiber-reinforced composites.

Here are some of the ways we are helping:

Rapid manufacturing has taken off in the automotive industry, delivering unprecedented speed and precision in parts production. We're seeing revolutionary changes in how quickly we can produce automotive components, with some parts being manufactured in as little as one day. This dramatic reduction in production time has transformed the traditional manufacturing landscape.

What's particularly significant is how these rapid manufacturing techniques are reshaping our industry's economics. We're experiencing significant cost reductions in overall manufacturing processes, while our supply chains are becoming more efficient through on-demand production capabilities. This shift allows us to maintain lower inventory levels while responding more quickly to market demands.

While rapid manufacturing propels production speed forward, robust quality assurance systems keep our standards high. We've implemented extensive quality management protocols that align with ISO 9001 certification, ensuring every automotive component meets precise specifications throughout the production process.

Our quality control doesn't end at production. We conduct thorough post-processing inspections to verify that every printed part meets safety and functionality requirements. These meticulous checks include surface finish evaluation, structural integrity testing, and dimensional verification. By maintaining these exacting standards, we're ensuring that our 3D-printed automotive components consistently deliver the reliability and performance that modern vehicles demand.

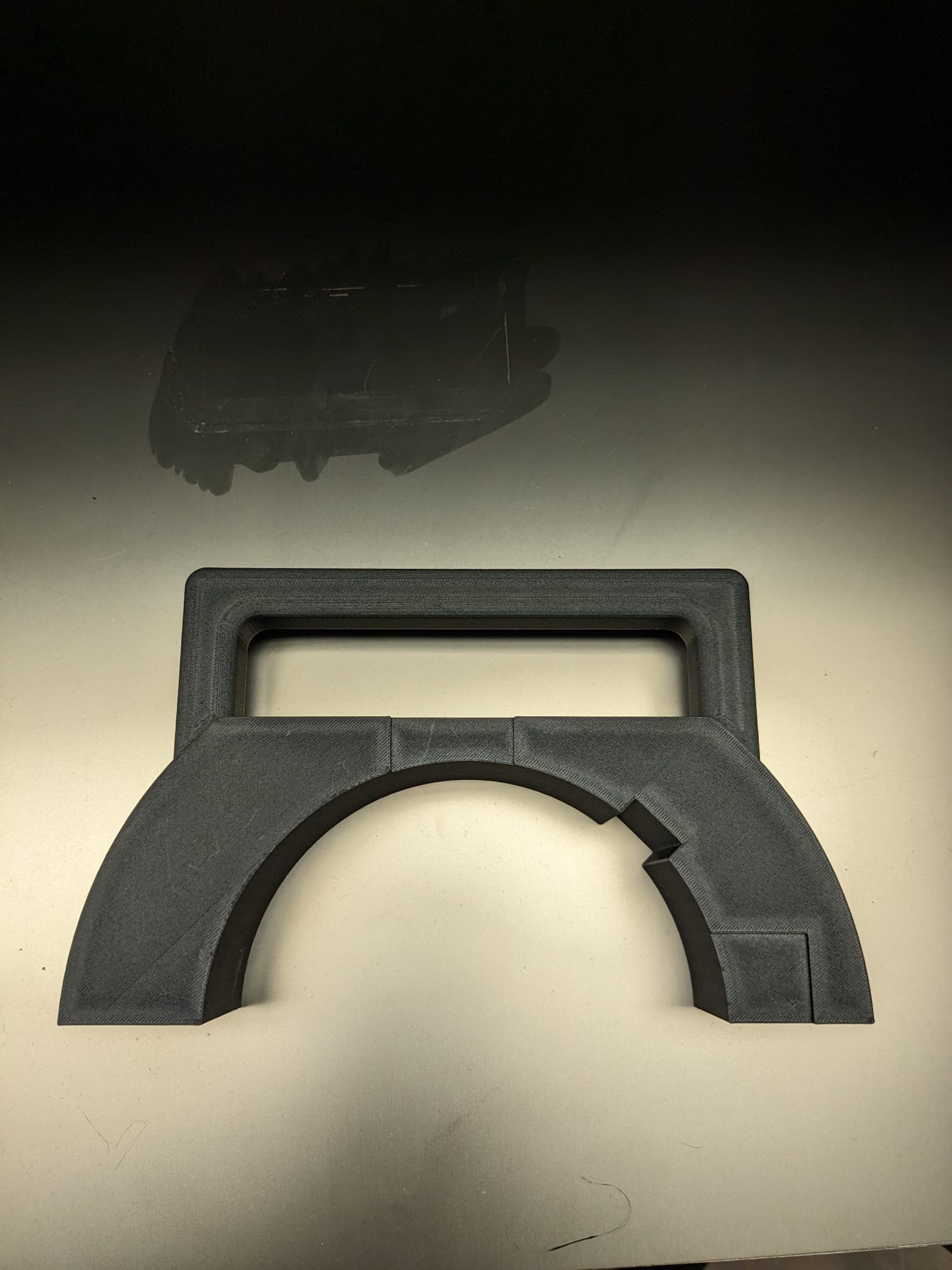

Our industry's precision prototyping capabilities have revolutionized automotive design validation. We're now able to achieve remarkably fine tolerances of +/- 0.1mm, which guarantees exceptional accuracy in testing and validation processes. Through advanced technologies like Stereolithography (SLA), we can create high-resolution prototypes with the smooth finishes that modern automotive designs demand.

The precision we achieve isn't just about the manufacturing process - it's verified through rigorous quality control measures, including detailed CMM Inspection Reports. These thorough checks guarantee that every prototype meets the strict standards our industry requires. We've found that this combination of rapid production capabilities and meticulous quality control creates an ideal environment for automotive innovation, allowing designers and engineers to iterate quickly while maintaining the highest levels of precision and accuracy.

Modern 3D printing technologies have transformed our approach to vehicle weight reduction. We're now able to produce automotive components that are considerably lighter than their traditional counterparts while maintaining the strength and safety standards that we've come to expect from modern vehicles.

The key to this remarkable advancement lies in our ability to work with advanced materials like carbon fiber-reinforced composites and high-performance thermoplastics. These materials, when combined with 3D printing techniques, allow us to create parts that offer exceptional strength-to-weight ratios. We're particularly excited about how 3D printing's design flexibility lets us create complex geometric structures that wouldn't be possible with conventional manufacturing methods.

Frequently Asked Questions About How 3D Printing Is Changing The Automotive Industry

3D printing in the automotive industry involves using advanced additive manufacturing technologies to produce parts, prototypes, and components faster, more efficiently, and with greater precision than traditional methods.

Some components can be manufactured in as little as one business day, depending on the complexity and materials used.

Yes, 3D printing can achieve tolerances as fine as ±0.1mm, making it ideal for precision prototypes and complex designs.

We use advanced materials such as carbon fiber-reinforced composites, high-performance thermoplastics, and nylon for their strength, durability, and lightweight properties.

By utilizing materials with high strength-to-weight ratios and designing complex structures not possible with traditional manufacturing, 3D printing can produce significantly lighter automotive components.

Yes, 3D printing supports scalable production through rapid manufacturing and just-in-time processes, enabling cost-effective, on-demand production.

3D printing allows for the creation of precision prototypes with smooth finishes and complex geometries, enabling faster design validation and iteration.

3D printing reduces costs through streamlined production, lower inventory requirements, and minimized waste, while delivering high-quality parts quickly.

Leave the questions here, we will answer you soon.